2013 BMW Z4 Engine Assembly

January 3, 2023

2017 Ford Fusion Engine Assembly

January 3, 2023Cummins QSB Engine for sale

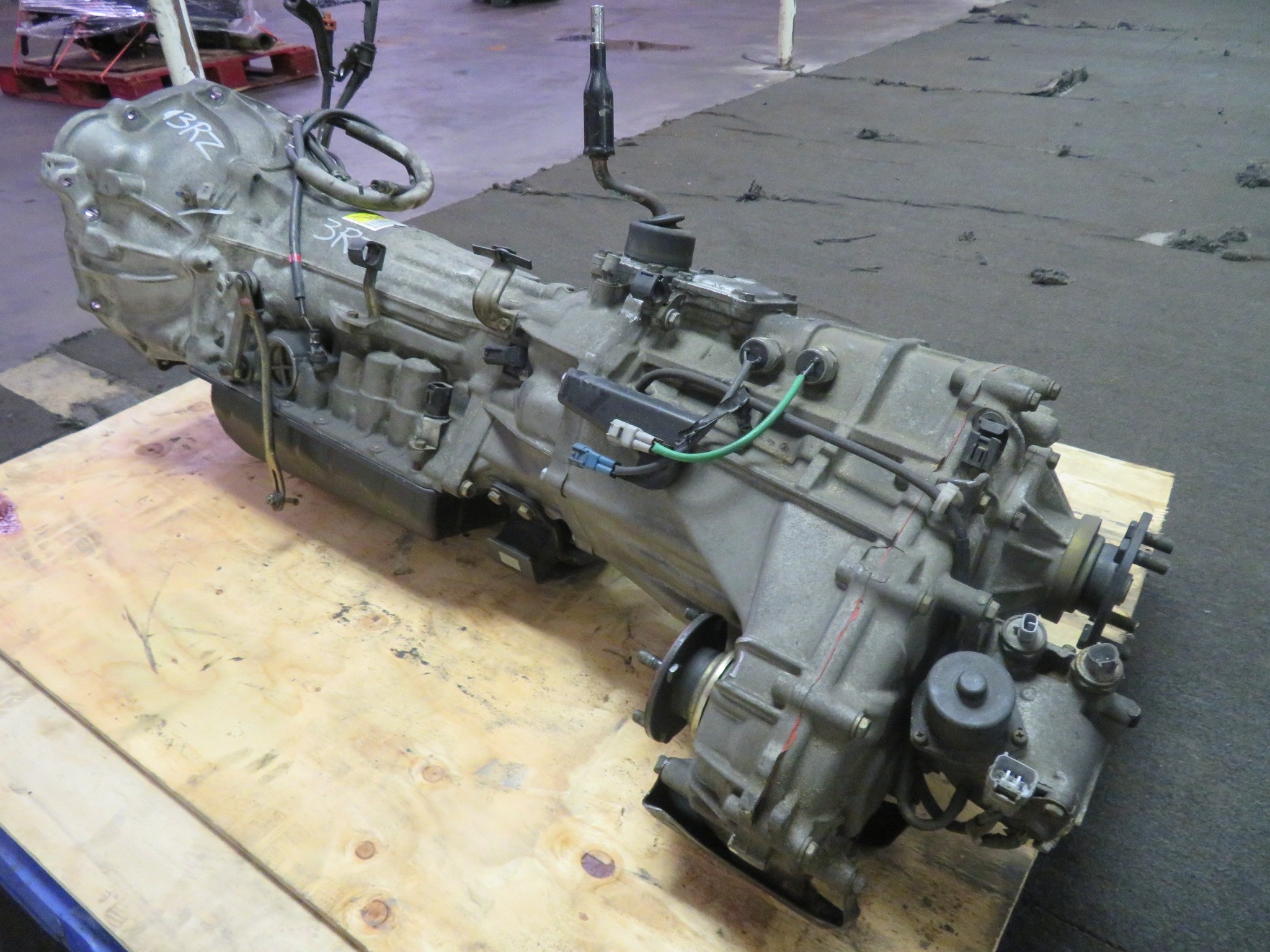

$4,500.00 – $8,400.00

Quantum System B, or 5.9L QSB Engine, is an off-road, heavy-duty variant of the ISB. These engines, which are typically employed in marine, agricultural, and construction applications, share many components with the ISB and make use of the same Bosch fuel system.

Quantum System B, or 5.9L QSB Engine, is an off-road, heavy-duty variant of the ISB. These engines, which are typically employed in marine, agricultural, and construction applications, share many components with the ISB and make use of the same Bosch fuel system.

Fuel system

Mechanical injection with mechanical timing

The older versions of the Cummins B-Series Engine, including its fuel system, were virtually totally mechanical. The P7100 injection fuel pump was used in these engines; it is powered by the camshaft gear and has a built-in camshaft to deliver fuel into each individual injector. Due to its straightforward design and high level of dependability, this pump was one of the most widely used solutions for fueling the B-Series Engines. With some minor adjustments to the system, the P7100 injection pump also enables the delivery of huge volumes of fuel into the system. QSB Engine

Mechanical injection with electronic timing

The fuel system was changed from mechanical injection and timing to mechanical injection with electronic timing in the later generations of the B-Series Engine. The new VP44 injection pump from Bosch is entirely to blame for this. The vertically centered injectors in the engine are popped by the VP44 injection pump, which is run at half the camshaft speed and generates fuel pressure at roughly 4,500 psi. To keep the system primed, these injection pumps require continual fuel pressure of at least 10 psi behind them at all times. QSB Engine

These pumps might quickly fail if they are used dry. The first pumps installed in the Cummins engine (QSB Engine) with an FPCM were the VP44 injection pumps. The fuel pressure control module, or FPCM for short, is in charge of regulating and maintaining the system’s fuel pressure. Although this new system for managing fuel pressure was practical, it had a significant drawback. The issue was that they couldn’t be serviced without a brand-new gasoline pump. QSB Engine

The gasoline transfer pump, which was situated on the side of the block next to the ECM, was a crucial component that contributed to the durability and functionality of the VP44. The injection pump requires a minimum of 10 psi from this electronically operated vane pump to maintain continuous fuel pressure as well as to cool and lubricate itself.

Mechanical injection with electronic timing and common rail pressurization

Common rail injection is the most recent fuel injection technique that is still in use today. Since a fuel pump is now utilized to pressurize a rail and then transport the fuel to each injector from there, common rail injection is a wholly novel approach to fuel injection. One significant advantage of using this feeding system was how little leaking into the cylinders occurred before and after ignition.

They were able to adjust spring tension higher in each injector to enable more precise fuel injection and timing because this fuel system functioned at pressures of up to 2600 bar. Another advantage of adopting common rail injection is that it is mo

| QSB Engine | Mechanical injection with mechanical timing, Mechanical injection with electronic timing, Mechanical injection with electronic timing and common rail pressurization |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.